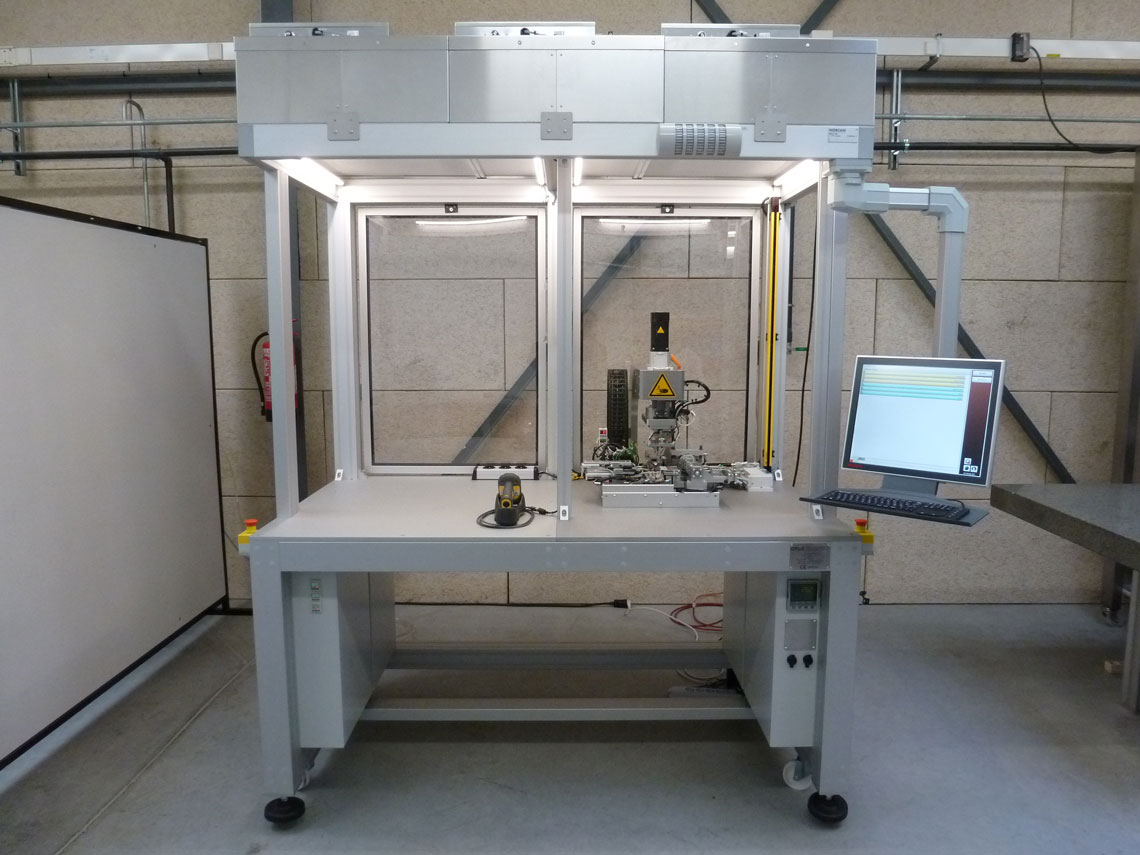

C10 Bonder: printer head bonding

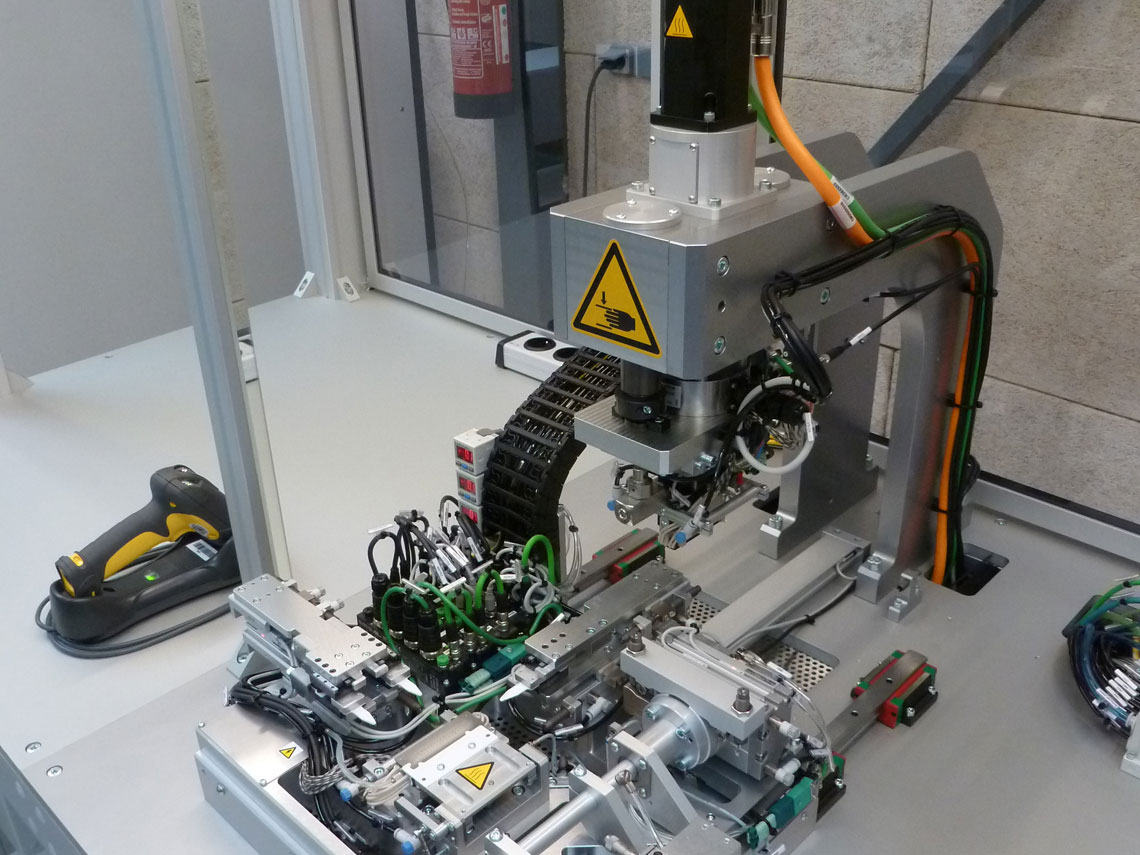

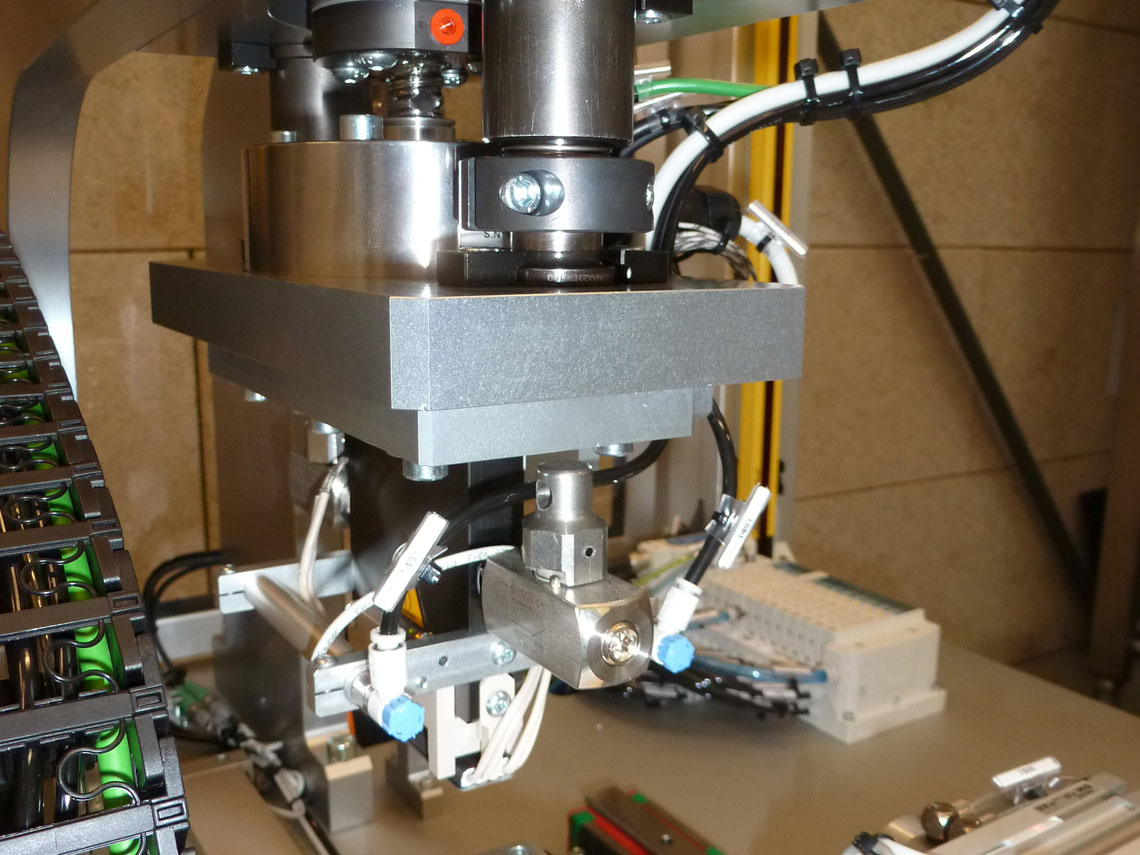

The ruggedized and enhanced version of the AU Bonder for mass production, dedicated to the piezoelectric assembly on a ceramic substrate used in the manufacture of industrial plotters print heads.

- Cleanroom and ESD design.

- Protection by light curtain with smart restart (process recovery).

- PC based with touch interface.

- Inputs-outputs and thermal controller on fieldbuses (Profibus and EtherCAT).

- Brushless motor with Galil axis control card, closed control loops for position and force.

- Visualization and real-time recording of process parameters (strength, positions, temperatures …).

- Different levels of access with maintenance key.

- Modular architecture allows the future integration of a second assembly station

- Adjustable laminar flows integration on roof.

- Fumes extraction through the assembly module.

- Barcode reader for production monitoring.

- Live saving of process data and report generation for each part.

- Intelligent condition monitoring routines to reduce operational downtimes.

- Rotatable, tiltable and height adjustable HMI.

- Smooth, bright and measured lighting.